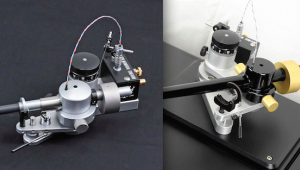

Brinkmann 9.6 tonearm

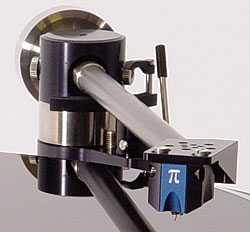

Brinkmann's 9.6 tonearm ($3990) resembles the German company's longer, more expensive 10.5 and 12.1 arms, which in turn resemble the legendary Breuer. The new arm includes the same headshell, armtube, mounting socket, and cueing device used in the other arms. The bearing system differs, though the Swiss-made ball bearings are identical.

Brinkmann's 9.6 tonearm ($3990) resembles the German company's longer, more expensive 10.5 and 12.1 arms, which in turn resemble the legendary Breuer. The new arm includes the same headshell, armtube, mounting socket, and cueing device used in the other arms. The bearing system differs, though the Swiss-made ball bearings are identical.

While the more expensive arms use traditional fixed-gimbal bearings, the 9.6 has a unipivot-like construction for the horizontal bearing. The weighted arm housing sits on a small ball that rests on a pivot, also as in a typical unipivot design. A second ball at the bottom of the housing prevents "arm lean," but since the arm's weight rests on the top ball, the lower one isn't critical, and I could feel some play when I handled the arm. Vertical arm motion is effected via a second pair of captured bearings. This arrangement allowed the use of less costly parts and kept the price down, Brinkmann says. The arm's effective length is 248mm (231.5 from pivot to spindle, plus 16.5mm of overhang), while its effective mass, referenced to the center position of the headshell slot, is 12gm.

The 9.6 arm's design is basic: The counterweight slides freely on a shaft aligned with the armtube and is secured with a grub screw, as is the vertical shaft used to set vertical tracking angle (VTA) and stylus rake angle (SRA). Setting the cartridge's vertical tracking force (VTF) is therefore less convenient than with a threaded rod, but if you carefully set the grub screw, you can nudge the counterweight along in small enough increments.

A threaded rod extending through the armrest platform to the base permits easy adjustment of arm height, hence VTA, after you've loosened a collar-mounted grub screw. This is less convenient than and not as easily repeatable as vernier-dial VTA adjustment, but unless you're delusional, you shouldn't need to change the arm height for every thickness of LP. The antiskating can be adjusted via a system of a magnetic ring opposed by a threaded pin magnet.

As with the other Brinkmann arms, the headshell has vertical walls that no doubt increase its rigidity, but also limit the width of the cartridges that can be used. Even if your wide-bodied cartridge of choice fits, be sure there's enough room to adjust its zenith angle. And as with some fixed-gimbal arms, the 9.6 offers no way to adjust a cartridge's azimuth. The arm's instructions include a method by which the azimuths of some cartridges can be adjusted by using a 10x or greater magnifying glass to insert, into the small lateral hole drilled in the rod that presses the transducer onto the rubber damper, a 0.8mm-diameter steel rod, and . . .

But don't even think about it. In short, what the 9.6 lacks in bells and whistles it made up for in the excellence of its machining and construction.

Setup and Use

If you order the Brinkmann Bardo turntable with the 9.6 tonearm and Pi phono cartridge, it will be delivered with the arm and cartridge already installed, even though there is no stylus guard. Not a problem, as you'll see when you unbox it.

After carefully removing a black nylon tie that holds the arm tightly to a rod threaded into the spindle, you place the arm on its rest, then remove the threaded rod and the orange protective tape around the subplatter-and-bearing assembly. Carefully place the heavy platter on the subplatter assembly, level the turntable, add the counterweight to the back of the arm, set the tracking force, and in less than 30 minutes you're just about ready to play records.

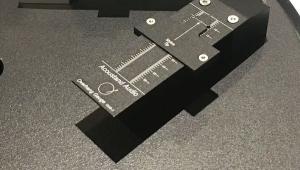

Brinkmann's specified pivot-to-spindle distance measured correctly per the latest Feickert gauge, but when I lowered the stylus onto the Feickert's overhang grid, it didn't line up with the scribe marks for the Lofgren, Baerwald, or Stevenson alignments. It was off by a few millimeters, which in this tiny world is a lot. I redid the overhang and zenith angle to conform to the Lofgren alignment, and contacted Brinkmann about this.

It turns out the original setting was deliberate. Brinkmann uses the Dennesen alignment protractor (in fact, he offers a nicely machined version of it) and a slightly different geometric methodology, describing the details of which space doesn't permit. As I say in my seminars on turntable setup, there are many ways of setting overhang to minimize tracking distortion. After our conversation, I returned the Pi's stylus to Brinkmann's preferred overhang position.

Using the Wally Tools Wallyskater, I found that the antiskating was set a bit too high—but again, skating is dependent on groove modulation, vinyl formulation, where on the record you measure it, and, for all I know, the day of the week. I suspect a modulated groove test was used to set antiskating; if that modulation was higher than what's found in typical musical signals, the setting will be too high.

When I checked the SRA with a digital microscope, I measured 90°, or 2° lower than what my experience has shown me is optimal. Raising the arm pillar 4° would produce an approximate 1° change in SRA, so I decided to raise it about 5mm, but not before listening to it as delivered. A digital oscilloscope and a Fozgometer (which in this case correlated well with each other) demonstrated that the Pi's azimuth had been set at the factory to perfection, which was fortunate—the 9.6 arm doesn't let you adjust azimuth.

Summing Up

The Bardo-9.6-Pi produced superbly well-organized sound with clean, sharp attacks, reasonably strong sustain, and pronounced decay, all against a jet-black backdrop. The harmonic structures of instruments, while somewhat lean, were intact.

The 9.6 tonearm is a very well made, basic design, but at $3990 it faces some stiff competition for not that much more money—competition that offers greater functionality, perhaps with greater dynamic capabilities and more precise extraction of information from the grooves.