Everything You Know About Skating Is Wrong!

Yes, skating begins with friction in the groove and it is caused by a “vector force”, but skating is not the result of your tonearm’s offset angle, either at the head shell or produced by an “S” shaped arm.

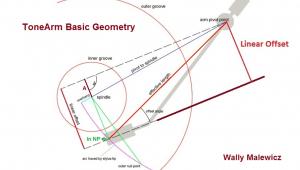

That’s what my late mentor Wally Malewicz taught me, and it turns out to be incorrect, as proven by a collaborative effort between Wally’s “right hand man” J.R. Boisclair and Wally’s son and mechanical engineer Andrzej. I like their water skiing analogy, about which you can read here. But before getting directly to the point, it’s key to remember why in the first place, pivoted arms have “offset angles” and “overhang” (I know many AnalogPlanet readers know all of this but hopefully this post will attract many others who don’t know this). Both are related to minimizing LTE (“lateral tracking error”). In the case of “overhang” it literally means the number of millimeters the stylus tip “overhangs” the spindle were you able to place the arm directly over the spindle. The actual arm length is the distance from the pivot to the spindle. The “overhang” is the distance from the spindle to the stylus tip. The arm’s effective length is the pivot to spindle distance plus the overhang. For instance, Rega’s older RB250’s geometry is: 222mm pivot to spindle, 15mm overhang and 237mm “effective length”.

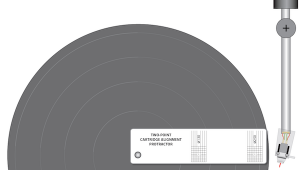

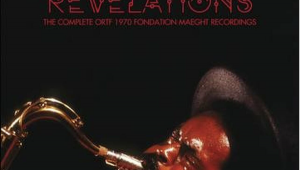

These videos are used permission of WAM Engineering Ltd.: In this first video you will see, using a blank record, (just for demonstration purposes don’t use a blank record to set anti-skating!), skating on a typical “S” shaped arm fitted with a spherical stylus cartridge, the importance of which will be discussed in a later video. Here, there’s an offset angle:

In this second video, the cartridge has been twisted in the head shell to eliminate the offset to 0 degrees and the skating force is for all intents and purposes identical to what’s seen in the first video. So much for “offset angle creates skating”.

In the third video the offset angle is negative, that is, beyond 0 degrees offset angle. The arm still skates. Of course this is with a spherical stylus, which I’m sure you now understand why using a spherical stylus was critical for this part of the demo. No matter what part of the stylus “sees” the record surface, the contact area remains the same.

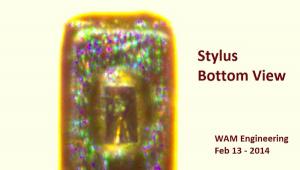

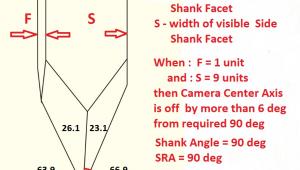

The contact area of a properly mounted micro-ridge or other “severe” profile stylus will be parallel to the record radius and produce little resistance to the skating force moving in the same direction. Twisting the cartridge to change offset angle as in the previous videos would put the stylus contact surface at an angle to the radius and thus produce more resistance to the skating force, which would alter the velocity and thus add fuel to the “offset angle produces skating” fire!

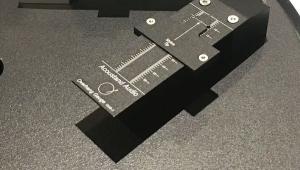

In the 4th video Mr. Boisclair clearly demonstrates why overhang produces skating, using a special arm mount that allows the arm to be moved forward to eliminate overhang. He then repeats the blank record test and the arm skates in until…… watch!

In the 5th video, again with overhang removed, the stylus is lowered towards the end of the record and the skating force reverses, causing the stylus to move away from the spindle and head back to the point of tangency perfection.

In the 6th and final video Mr. Boisclair defines tangency for those of you who are mathlexic (which includes me!). He then returns the arm to its correct pivot to spindle distance, which again produces the specified overhang. The arm then skates towards the record center and he shows you how doing so swings the tangent line, which is then at a significant angle to the line formed between the stylus and the pivot causing a sideways force, which is our skating force as analogized by the water skier in the picture at the top of this story!

Conclusions

Skating is real. Not compensating for it makes no sense. The geometry of Increased tone arm length does result in a lower offset angle but that does not decrease skating by any appreciable amount and is therefore not among the advantages of a longer tone arm. Creating a tonearm with zero offset angle does not eliminate skating. Creating a tonearm with no overhang does eliminate skating at the point of tangency as demonstrated in the video, but only at that point and in fact, beyond that point the arm produces its own “anti-skating” as it wants to return to the point of tangency!

Tangential pivoted arms such as HiFiction's Thales arms do skate, and that is why the Thales arms do incorporate anti-skating compensation.

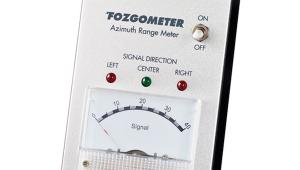

The discussion of how best to set anti-skating, in which readers and Mr. Boisclair all engage following the Wallyskater V2.1 coverage is well worth reading. It also demonstrates that AnalogPlanet has the best, most constructive readers and knowledgeable readers.

Finally here’s Mr. Boisclair’s Skating PowerPoint Presentation.