Tonearm Reviews

Sort By: Post DateTitle Publish Date

|

Aug 01, 2018

|

Jan 14, 2006

|

Jan 30, 2018

|

Dec 29, 2020

|

Apr 22, 2007

|

Jul 08, 2014

|

Oct 07, 2018

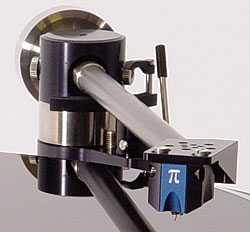

Brinkmann's 9.6 tonearm ($3990) resembles the German company's longer, more expensive 10.5 and 12.1 arms, which in turn resemble the legendary Breuer. The new arm includes the same headshell, armtube, mounting socket, and cueing device used in the other arms. The bearing system differs, though the Swiss-made ball bearings are identical.

Brinkmann's 9.6 tonearm ($3990) resembles the German company's longer, more expensive 10.5 and 12.1 arms, which in turn resemble the legendary Breuer. The new arm includes the same headshell, armtube, mounting socket, and cueing device used in the other arms. The bearing system differs, though the Swiss-made ball bearings are identical.