The Last Word (For Now) on the Technics SL-1000R Tonearm

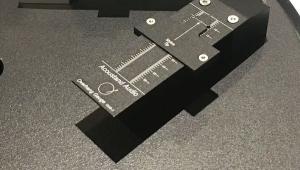

So I measured the pivot to spindle distance and it was 239mm. Add the 15mm overhang and the actual effective length of the arm was actually 254mm. It turns out that Technics uses the term "effective length" to describe the actual length that's normally defined as the pivot-to-spindle distance! To its credit Technics has changed its specification nomenclature to avoid future confusion.

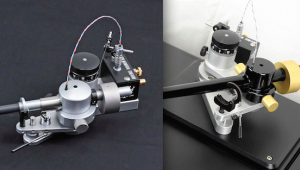

In the meantime, my friend and mentor Wally Malewicz has take the time to prepare the above chart that hopefully will clarify many of the faux controversies under the previous SL-1000R story. The chart shows you (reading from right to left) the null points and % distortion when setting up the SL-1000R using various alignments. As you can see, both the "new" Technics alignment and Stevenson alignment produce the lowest distortion at the inner groove area and therefore if you play mostly older records that tended to be cut closer to the label, there's a benefit to using either of those, though as you can clearly see, distortion throughout most of the record is considerably higher than with either Lofgren A or B.

Also obvious is that if you play mostly newer records that are not generally cut close to the label, you are much better off aligning using either Lofgren A or B. When I chose to not use the Technics overhang gauge and instead used the WallyTractor, of course the overhang was different than the result using the Technics gauge, but it's what I prefer: lower distortion throughout most of the record, with higher distortion at the end, but not really a problem on modern records.

Which alignment you choose to use is up to you! Arguing over it is just plain stupid and a total waste of time!