Analogplanet Visits Stoughton Press

Last December while in the area for the L.A. and Orange County Audiophile Society annual gala where I roasted Chad Kassem, we visited one of the world's leading record jacket manufacturers (if not the leading manufacturer) to see how record jackets are manufactured in the 21st century.

The vast majority (more than 90%) of the company's business is printing and fabricating record jackets. This new press will ease the load on the company's original Heidelberg press, which has been operating overtime.

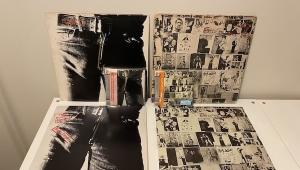

What we saw at the plant confirmed what we long suspected and which last year's number of records actually pressed also confirmed: the actual number of records sold last year and this year is absurdly greater than the numbers reported by Soundscan/Nielsen. For instance: S/N reports about 70,000 copies sold of Jack White's Lazaretto album, yet Stoughton printed 170,000 jackets.

Why? Because that's the total number ordered by White's label, probably incrementally. Does anyone think White ordered 170,000 jackets because he likes to waste money on jackets and storage? So on this one record S/N has grossly underreported sales. As you'll see, upon entering the press room we came upon stacks of Fleetwood Mac Rumours jackets—around 11,000 of them—this order coming years after the record's 180g reissue on both 33 1/3 and 45rpm. This success just kills the naysayers. They are in denial.

Giving us the tour is Jack Stoughton, Jr. son of the company's founder. As you'll see, Stoughton Junior learned well from his father and his knowledge of and enthusiasm for this process is impressive.

Also on board (among others) is music fanatic Rob Maushund (the longer grey bearded gentleman), who came to Stoughton for a temp job but stayed on (and on and on), and Acoustic Sounds' Chad Kassem. The less Z.Z. Top-ified bearded guy with the glasses is QRP plating master Gary Salstrom.

Unfortunately we were unable to show you some elements of jacket production because some of what Stoughton does to produce its patented "Tip-on" jackets is proprietary and the company doesn't want it documented.

Of course the "Tip-on" paper on cardboard jackets are the most expensive and coveted both because they look and feel best and return jacket making to the great early days and because they are time and labor intensive to manufacture.

As you'll see in the video it takes a great deal longer to make "Tip-on" jackets than the automated process used to manufacturer direct-printed jackets. It would not be giving up a trade secret to tell you that if you examine a "Tip-on" jacket in your collection you'll note that the back panel is glued directly to the back cardboard panel, over the album's front paper, which is folded and glued to the back. Skilled, experienced workers affix those back panels "free form" by hand!

Enjoy the tour: