Updates and Corrections to Recent Technics SL-1000R Preview Story

As I've always understood and used the term, an arm's actual length is defined by its measured pivot to spindle distance as indicated in the illustration provided me by Wally Malewicz some years ago. The "overhang" is literally the number of millimeters the stylus extends beyond the spindle, usually between 15mm and 18mm. Extending the radius of the stylus arc beyond the spindle's center reduces tracking error as well described by Keith Howard in this 2010 Stereophile article: ".... the radius of the stylus (needle) arc had to be greater than the distance from the arm pivot to the center of the disc, by a distance that today we term the overhang; and the pickup cartridge had to be twisted relative to a line joining stylus to arm pivot by an angle termed the offset."

You have to be careful reading about this subject on line because you can just as easily find this definition of "overhang" written by an ignorant knucklehead on Audiogon: "Overhang is a term used to describe the incorrect tracking path of the stylus for cartridges mounted in a pivoted tonearm. Overhang is not a problem with linear tracking arms, which track in a straight line directly across the record (the same path followed by the cutter head when LP masters are cut)".

In any case, an arm's effective length is defined as its actual length (pivot to spindle distance) plus the overhang, but for some reason Technics uses the term "effective length" to describe the actual length of its arms to which it then adds the overhang. I didn't know or remember that when the SL-1000R was delivered so the "effective length" spec of 239mm did not "add up". It must be a mistake I thought.

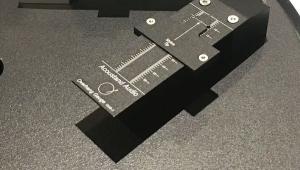

So out came the Acoustical Systems SMARTractor to measure the P2S distance and sure enough the arm's P2S distance, not its effective length was 239mm! The arm's true effective length was 254mm not 239mm. I was correct enough about that, but that led me to make some mistakes conceptual and otherwise.

I used my WallyTractor universal overhang gauge, which includes Baerwald and Löfgren arcs for 13 different effective length arms, including one for 254mm, which corresponds to Immedia's RPM-2 and Centroid arms. However, the stylus as set using the Technics overhang device did NOT match either the Baerwald or Löfgren arcs! And that is where my thought process careened off the road.

First, I thought this confirmed that Technics had made a serious error and that if I wanted the Löfgren A alignment I'd have to re-do the overhang using Wally's gauge, which is what i did and that's how I listened. However, had I left the overhang alone, as it was set up using the Technics gauge, that would have been correct, based on Technics' calculations though they don't reveal the source of their geometry. In any case, you can pretty much set up any arm using Baerwald, Löfgren, Stevenson or UNI-DIN and get different but acceptable results. Since the "null" points are based upon never kept standards as to where the lead in and lead out groove areas start and stop, there's definitely room for some "play".

Nonetheless, I apologize for making Technics look like its geometry was in error, when it was not. My conceptual error was not realizing that since the Technics overhang gauge is a head shell holder that duplicates the arm terminating collet, the overhang setting must be correct for whatever is their geometric calculation. Whether or not what I came up with resulted in a gross error or simply another but different solution is something about which I'm not yet certain. I've got an email in to Wally for his explanation.

Other Corrections

Technics' Bill Voss emailed this morning with a few other corrections to the original story:

1) One of Technics' heavier Ortofon head shell options would have easily solved the measured resonant frequency issue noted in the story.

2) I erred writing that the you can swap out the main arm board with another one to mount your choice of arms. That is not true. The only arm useable in the main mount is the Technics arm. The secondary mounts can accommodate a variety of other arms.

3) Technics does not supply a DIN to RCA cable for its arm. That is up to the buyer.

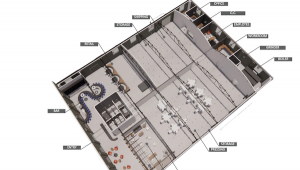

4) There are currently 10 variations of armboards that can be installed in the 2 open positions on the back and left side of the SL-1000R plinth.

5) The SL-1000R plinth is not available as a separate product.

Finally you can download here Technics brochures for the SL-1000R and SP-10R.

I hope that clears it all up! However I hope Technics checks into how the term "effective length" is used throughout the world and considers adopting it too, to avoid future confusion!