rave review many years ago. I got deja vu when I read his comments "Still, I guess you could balance it all out with an appropriately sharp cartridge and some wiry-sounding electronics and/or speakers." and "Romantic? Yes. Musically enjoyable, soothing, and relaxing? Yes. Lifelike? Not to my ears." I know MF has the type of system that is quasi "perfect" - the perfect blend of detail and romantic. I can't afford that so I opt to lean towards the romantic side of things in the ongoing "compromise" that is being an audiophile.

Analog Corner #96

Viola had much to be proud of: He'd developed a massive, true air-bearing platter—one that "floated," both radially and axially, on a thin film of air—and his tonearm featured a captured air bearing modeled after Andy Payor's Rockport design. While Payor's arm uses a bearing-and-rail assembly made by a company specializing in air-bearing machine tools, Viola rolls his own. But on closer inspection, the models on display at Top Audio, for all their gleaming metallic beauty and rococo good looks, struck me as underdeveloped and unfinished.

Would Viola continue his development and finish the work he'd begun? Would he be capable of building reliable finished products? Would his company survive? Three years later, the answer to all three questions seemed to be "Yes." The 'tables have apparently found a following around the world, and V.Y.G.E.R. now has an American importer, Acoustic Dreams, so a review seemed like a good idea. For reasons of space, I chose the $33,500 tabletop Atlantis with vacuum holddown. It weighs 160 lbs, so you'd better have a sturdy 'table table.

V.Y.G.E.R. Atlantis

Despite its exotic air-bearing platter and tonearm, the V.Y.G.E.R. Atlantis's subchassis support system is a conventional three-point design modeled after SME's, though on a much more massive scale. The design features a series of looped O-rings at each tower for vertical suspension and a viscous bath for horizontal control of the 77-lb subchassis, which is machined from a solid block of aluminum and fortified with 20 lb of lead. The entire base assembly weighs 122 lb.

Curiously, the custom-made AC synchronous motor is similarly isolated via an elastomer suspension of some sort at the motor pulley shaft, making it possible to wiggle the pulley back and forth. This makes no sense to me—it allows for microvariations in the distance from pulley to platter that, in my experience, mean microvariations in speed. The motor itself is outboard, isolated from the rest of the 'table via the suspension and the round rubber drive belt, so what this motor-shaft "suspension" is supposed to accomplish is beyond me.

The 30-lb aluminum platter has an outer ring of lead for increased moment of inertia. It rides on a thin film of pressurized air (1.5–3 Bar) via a precision spindle of unusually wide diameter, made of high-carbon, corrosion-resistant, martensitic steel. (Martensite is the hard constituent that is the chief component of quenched steel.) According to Viola, the spindle has a rotational precision of 0.5–1µm. Viola also claims to have, "for the first time in the record-player history," made a platter that is a true air-bearing design both axially and radially—but surely he's heard of the Rockport design, which did likewise many years ago.

Vacuum holddown is accomplished via two concentric "lips" of rubber (or a rubber-like material) that sit in grooves machined into the platter's acrylic surface, which is secured to the platter with five hex-head screws. Air is drawn out along channels in the platter surface and down through a circular groove adjacent to the threaded shaft of the record spindle.

Matching the mass of the spinning system is the gargantuan assembly of the tangential air-bearing tonearm—it looks like an Andy Payor design on steroids. Weighing around 11 lb, it features a rail on which the captured bearing slides on a film of air, a secondary tubular support for added rigidity, and a third, smaller tube used for cueing. The three tubes attach to one of a pair of connected towers supporting the entire mechanism. A cap on the other end of the arm assembly adds another level of rigidity to the three tubes. The main tower encloses and rides on a stable threaded mechanism that allows for precise adjustment of vertical tracking angle (VTA), and is secured to a circular base plate that attaches to the subchassis. A feeler protruding from the tower rests on the base plate; as the tower moves up and down, it actuates a dial gauge, allowing for precise and repeatable VTA settings.

The second tower includes an air regulator that lets the user vary pressure to the bearing, though why anyone would want less than maximum stiffness is a mystery to me—unless you want to "tune" the air bearing's mass/compliance resonance away from exciting the fundamental resonant frequency of the arm-and-cartridge assembly. (A properly designed "orifice-compensated" air bearing will not have such a resonance, I believe.) Would you want to be able to loosen the precision of a gimbaled bearing? I don't think so! All things being equal, higher air pressure creates a stiffer bearing for more precise performance. Lower pressure yields more play and a softer, warmer sound. Count me out of that camp!

The hollow, tapered armtube is approximately 7½" long from the headshell to the center of the air-bearing "pivot," and supporting structures are made of magnesium to maximize stiffness and minimize weight. The air supply consists of a surprisingly compact oil-bath compressor enclosed in a 15mm-thick aluminum chassis. There are also a sophisticated filtering system and a cylindrical pressure-stabilizing unit.

Setup

While Acoustic Dreams will most likely set up your V.Y.G.E.R., watching the process and making certain adjustments myself led to me some discomfort about a few aspects of the design. First, there's the interface of arm assembly and subchassis: a wide slot in the armboard, through which fits a large-diameter bolt that protrudes from the arm's baseplate. Sliding the arm fore and aft in the slot accomplishes rough "overhang" adjustment (it's not really overhang, but an adjustment to assure a radial tracking line across the record surface and tangency to any groove along that line). Because the heavy arm assembly can also rotate around the bolt's vertical axis, setup becomes a somewhat cumbersome, sometimes frustrating procedure—but if it's being done for you, why worry?

Once the arm had been properly situated using a straight-line gauge that goes over the spindle, I tightened a large plastic nut to secure the arm to the armboard. It's not exactly an elegant or ultra-rigid solution. Fine "overhang" and azimuth adjustment are accomplished by loosening a pair of small set-screws that secure a shaft protruding from the rear of the armtube. This allows you to move the armtube back and forth, and to rotate it around the shaft axis to set azimuth.

After leveling the subchassis-platter assembly with the three suspension towers, I adjusted a series of pointed set screws located around the arm's baseplate to level the arm itself. This is the interface that gave me the greatest cause for concern. V.Y.G.E.R. and Acoustic Dreams suggested that the arm rail be set with a slight downhill bias toward the spindle. This is accomplished by screwing down the three set screws on the right side of the tower base so that they press against the armboard below, thus raising the right side of the base.

First, having to put a downhill bias on the rail means that the azimuth will change across the surface of the record. (I had a similar problem with the original Clearaudio-Souther arm's setup instructions.) Second, it means downward pressure of the screws on the baseplate. Over time this pressure surely will shift, resulting in instability. In any case, having the armboard cantilevered by pointed set-screws compromises rigidity, I feel.

The armtube itself is undamped and hollow, its internal wires permitted unrestricted motion. This surprised me—the hollow, air-filled cavity will certainly resonate. The arm wires themselves are left to be draped as you wish down to a terminal block mounted on the 'table's base—another less than elegant solution. With the arm wires running from the back of the armtube and out a slot near the interface of the tube and bearing assembly, there's no place for a damping trough (though a cap on the side of the main tower may indicate further development).

While a car can be driven with a spring suspension and no shock absorbers, the ride will not be pleasant or safe. A virtually friction-free but undamped bearing system simply doesn't make sense to me. I don't have space here to go into all of the reasons, which I covered in my review of the Rockport Series 6000 arm, in the May 1996 issue (Vol.19 No.5). In my opinion, damping is beneficial in any tonearm, but it's critical for a linear air-bearing design, which, when properly executed, has virtually no friction.

Not damping the fundamental vertical and horizontal resonances, which in a linear arm will be very different because of the differences in horizontal and vertical mass, can create serious tracking and/or sonic problems. In the horizontal mode, the entire arm assembly moves; in the vertical mode, there is a shorter armtube than in a pivoted arm. Both contribute to the wide potential disparity between the horizontal and vertical resonant frequencies. At the very least, there should be vacuum holddown to flatten the record surface and reduce the excitation of warp/wow resonances. The V.Y.G.E.R. Atlantis has that, at least.

When I measured the fundamental resonances of the Atlantis arm using the Hi-Fi News Analogue Test LP and the Lyra Titan or Transfiguration Temper W cartridge, I found the horizontal resonance was excited from 7–8Hz down to the LP's minimum test frequency of 5Hz. Did the resonance extend below 5Hz? I don't know, but 5Hz is too low in that it starts to overlap of warp-induced wow. As the test frequencies descended to 5Hz, there seemed to be no letup to the excitation, so I'd guess that, yes, the resonance did go below 5Hz, which is not good. Because of the large horizontal mass—the entire arm and bearing assembly—the excitation caused alarming motion, the cantilever wiggling back and forth almost to the point where the tail (arm) was wagging the dog (cantilever). A damping trough would have minimized this behavior.

If this resonance occurs during normal playback in the 8–12Hz region, there's little to worry about: it's above warp/wow and below musical frequencies, so there's little chance it will be excited—which is why you ideally want it to lie between 8Hz and 12Hz. If the resonance continues below 5Hz, record eccentricity might excite the resonance and create serious tracking problems.

I could find no resonance at all in the vertical direction, meaning the resonance was probably above the 20Hz upper limit of the test record, and therefore within the range of music. That means musical frequencies will excite the undamped resonance, and low-frequency response would most likely suffer. I contacted the importer about this finding.

An email from the designer (paraphrased by the importer) claimed that the vertical resonance should lie around 9Hz but that it "is very difficult to see because of its very small amplitude. The air bearing and air tube [are] designed to dampen the vertical resonances." It went on to say that the designer's "Dynamic Control Design is proprietary but I can say that all the turntable materials were very carefully chosen along with his air-flow design to keep the table resonance down when playing, especially during hard attacks. Again, since his system works so well it may not be able to be detected using conventional methods."

The fundamental system resonance that results from the cartridge compliance and the tonearm mass, whether linear air-bearing or pivoted, is not dependent upon program material unless the resonance falls within the encoded frequency range (which hopefully it does not). Its excitation begins the moment a stylus is lowered into the rotating groove.

Why the amplitude here would be small is not clear to me. I cannot understand how the bearing and/or the air tube in a virtually frictionless system can dampen the resonance, or why I would not see it or hear the warble of the pilot tone that accompanies the 9Hz frequency on the test record. I have always been able to detect a resonant frequency using this test record if the resonance lies within its 5–20Hz frequency range. I performed the same test on the Immedia RPM-2 (synthetic oil damped) and Graham 2.2 (silicone damped) tonearms; both had easily viewable and audible horizontal and vertical resonant frequencies within the ideal 8–12Hz range, using this test LP.

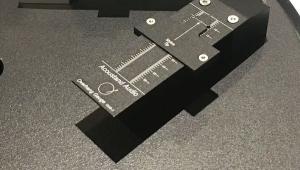

Getting a beginning VTA reference point parallel to the record with a bodiless cartridge such as the Lyra Titan was extremely difficult. The Atlantis's armtube is tapered, and, unlike with the SME V, for example, there is no horizontal leveling line to use as a reference. Luckily, I have the WallyTools WallySkater, which provides a precise way to begin with the armtube parallel to the record surface. Having easily adjustable and repeatable VTA is a wonderful feature, but the inability to set a reliable reference point makes it difficult to use.

I first set the rail angle as instructed—with a slight downward slope (0.2 on the Cartridge Man's digital level)—and found that the downslope bias put the arm farther downhill than the stylus, resulting in a seriously off-kilter cantilever. I leveled the rail, found the cantilever nicely centered, and encountered no sticking problems throughout the review period, as long I remembered to clean the rail by running the bearing across it a few times to remove dust—something you have to do with any air-bearing arm.

I'll say this: The Atlantis arm's air bearing worked as advertised. But whether or not Giuseppe Viola has created a genuine orifice-compensated air bearing—in which the high pressure needed for bearing stiffness at the "work zone" gradually decreases to ambient air pressure at the orifice (where the air exits at the bearing/rail interface)—is something I can't answer.

On the plus side, the compressor system was so quiet that I was able to keep it in my listening room only a few feet from my chair—it was inaudible even when no music was playing. However, when the oil bath warms up, it does smell and you should be prepared for a slight "machine-shop" olfactory room "ambience." Also, the Atlantis ran within a hair of 331/3rpm; a 1kHz test tone measured 990Hz, which is excellent.

Use

Using the Atlantis was easy and fun. I flipped on the compressor using the plinth-mounted switch, first to the Up position for a few seconds to clear out the air passages, then Down to pressurize the platter and arm bearings. This took only a few seconds, and is verifiable via the air-pressure gauge mounted next to the switch. I ran the arm across the rail to clear the dust, and, after carefully cleaning the platter surface, put a record on it. Cleanliness of platter and record are critical—the platter surface, unlike the Rockport's, is hard, and any dirt will be pressed into the record by the vacuum. I then screwed on the heavy, nicely machined aluminum clamp, hit the vacuum switch, and the air evacuated from the LP/platter interface, sucking the record down flat. The vacuum pressure was automatically withdrawn a few seconds later, but the seal remained. I waited a few seconds more for the pressure to return, flipped the motor switch on, lowered the stylus, and...

The Atlantis Sounds Off

Playing records the way they were cut offers certain obvious sonic advantages, including an enormous, airy soundstage and a freedom from the typical distortions caused by the tracking errors created by pivoted tonearms. On the best pivoted arms these are not heard not so much as "distortion" but as a slightly pinched or bright sound. Once you hear a true linear tracker (not one that meanders across the record), you'll hear an open, sweet sound that approaches that of reel-to-reel tape.

The Atlantis had that open, airy sound. It was both pleasing and dramatic, with a sensual, liquid caress that made strings sing lushly. The Heifetz/Piatigorsky performance of the Brahms Double Concerto (RCA Soria LDS-2513) was an absolute delight decoded by this turntable, as was the Leibowitz/RPO Beethoven 6, from the Reader's Digest boxed set. But, as I'd expected from the resonance measurements and the lack of damping, the Atlantis's overall sound was on the warm, sweet, somewhat "fat" side. Images were big, rounded, and three-dimensional, with soundstage width, depth, and height appropriately sized to accommodate them.

The Atlantis produced a sonic picture I've seen showgoers at the Consumer Electronics Show lap up in room after room, and especially at THE Show, where some of the smaller, tweakier companies exhibit—but having just attended a few symphony concerts, I don't hear a strong relationship between the Atlantis's soft, sweet sound and what I hear live. Still, I guess you could balance it all out with an appropriately sharp cartridge and some wiry-sounding electronics and/or speakers.

I couldn't fault the V.Y.G.E.R. system's dynamic slam, or the harmonic presentation of the midbass through the upper midrange, which had weight, texture, and physical presence. But high-frequency transients were softened and somewhat dulled compared to live, and the bottom end in particular lacked punch, drive, and extension. Romantic? Yes. Musically enjoyable, soothing, and relaxing? Yes. Lifelike? Not to my ears.

I went back to some recordings I'd used in my May 1996 review of the Rockport Series 6000 tonearm, including The Newport Folk Festival: 1963, Vol.2 (Vanguard SH 114, an original Japanese pressing from 1964). One track features 11 singers—Bob Dylan, Peter, Paul & Mary, Joan Baez, the Freedom Singers, Pete Seeger, and others—strung across the stage singing Dylan's "Blowin' in the Wind." There's a photo on the jacket showing the singers, a stereo mike pair in front of Dylan. I remember the placement perfection the Rockport 6000 delivered—the width of the stage, the sense of the outdoors, and especially the image focus, the delineation of the singers, the sense of the stage backdrop, the night air. The Atlantis superbly rendered the stage width and the spread of the group, but the pinpoint image focus was diffused, as was the delineation of the singers and the backdrop.

I threw on John Hiatt's "Lipstick Sunset," from Bring the Family (Mobile Fidelity 1-210). While the sonic picture was enormous and Hiatt's voice had a warm, rich, natural texture, the delineation of it and the studio-induced reverberant field was diffuse, and Ry Cooder's slide guitar lacked shimmer and spine-stiffening tingle.

I was able to easily switch back to the combo of Simon Yorke Series 7 turntable with Immedia RPM-2 and Graham 2.2 tonearms for comparison on both the Newport and Hiatt LPs. Yes, the cartridges were different, but the fundamental differences between the turntables held in terms of transient speed and clarity, treble and bass extension, and overall image size and focus. The Yorke combo won hands down, though the Atlantis had quieter backgrounds. Gone, though, from the Yorke's presentation was the enormity of the picture, as well as the liquidity and sweetness and a certain ease and openness that had more to do, in my experience, with linear tracking than the areas where I felt (and measured) that the Atlantis arm was not performing adequately.

I'd love to hear what the Atlantis might sound like with a good pivoted arm; I don't feel V.Y.G.E.R.'s linear-tracking arm performed at the same high level as the turntable itself, though I'm curious about the rationale behind the gummy motor shaft.

Conclusions

The V.Y.G.E.R. Atlantis is a superb turntable mated to a tonearm design that needs work, specifically: silicone damping via a trough, internal armtube damping, a more elegant way of dealing with the cartridge wires where they exit the arm, a more stable arm/'table interface, and, especially, some kind of mass reconfiguration to get both the horizontal and vertical resonant frequencies as close as possible to the 8–12Hz ballpark. These fundamental performance issues need to be addressed before the Atlantis can be considered a truly finished product.

On the other hand, if you like the Atlantis's sound—and who doesn't like its looks?—don't let me stop you. But for $33,500, you're entitled to a 'table that gets the fundamentals correct, and in my opinion, this one's tonearm misses a few.

Sidebar: In Heavy Rotation

1) Christopher O'Riley, Plays Radiohead, Sony Classical CD

2) Ella Fitzgerald, Sings the Rodgers and Hart Song Book, Speakers Corner 180gm LPs (2)

3) The Lovin' Spoonful, Hums of the Lovin' Spoonful, Sundazed 180gm LP

4) The Kinks, Low Budget, Mobile Fidelity SACD

5) Various Artists, Reflections on Peter Green, Audio Fidelity 180gm LPs (2), SACD

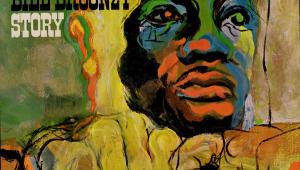

6) Muddy Waters, Sings Big Bill Broonzy, Speakers Corner mono 180gm LP

7) Lee Morgan, Candy, Classic Quiex SV-P mono 200gm LP

8) Uncle Tupelo, 89/93: An Anthology, Sundazed 180gm LPs (2)

9) John Coltrane, Soultrane, Analogue Productions 45rpm, 180gm mono LPs (2), Mobile Fidelity mono SACD

10) Eddie Henderson, So What, Eighty Eight's LP, SACD

- Log in or register to post comments

It sounds like Giuseppe Viola's dedication and craftsmanship have truly paid off, transforming his initial doodle jump creations into a successful line of high-end audio equipment.